Prysmian Group deployed RealWear HMT-1 running Engineering Group with OverIT’s SPACE1 augmented reality application to drive remote acceptance testing and knowledge transfers.

Prysmian Group is a multinational company headquartered in Milan, Italy. It’s the largest manufacturer of telecommunication cables.

The Challenge

Prysmian Group needed a more efficient and cost-effective process to connect field operators to a vast network of internal and external experts.

The Solution

Prysmian Group deployed RealWear HMT-1 running OverIT’s SPACE1 augmented

reality application to drive remote acceptance testing and knowledge transfers.

The Results

- Enabled remote acceptance test

- Increased field operator safety

- Streamlined knowledge transfer

- Reduced systems experts’ travel

- Overcame pandemic’s travel restriction challenges

Hands-Free Use Case

- Remote Acceptance Tests

Prysmian Group is the world’s leading manufacturer of electronic power transmission and telecommunication cables. With nearly 30,000 employees and more than 100 plants in over 50 countries, Prysmian Group wanted to improve how it can better support internal operations and coordinate knowledge transfers of complex and advanced telecommunications systems.

“Being in a leadership position also means leading the market, directing its decisions and choices,” explains Stefano Brandinali, Prysmian Group’s CDO & CIO. “To maintain this leadership through time, innovating becomes crucial.”

This manifested in a goal to revamp how field operators can more efficiently connect to Prysmian Group’s vast network of internal and external experts.

Creating Opportunities with RealWear

The company turned to Engineering Group, a digital transformation consulting firm and parent company of OverIT, and RealWear to establish a digital platform “PG Connect”. PG Connect is an in-house initiative designed to better connect on-field operators to system and component experts.

Ease of collaboration was a key aspect to this project, and the RealWear HMT-1 headset checked all the boxes. Its voice-activated controls enable operators to access and view documents, multimedia and other file types on a low-profile micro-display. The high-resolution camera captures videos and images from the wearer’s perspective, and the wireless connectivity allows real-time collaboration between the onsite operator and the remote expert.

Ease of collaboration was a key aspect to this project, and the RealWear HMT-1 headset checked all the boxes. Its voice-activated controls enable operators to access and view documents, multimedia and other file types on a lowprofile micro-display. The high-resolution camera captures videos and images from the wearer’s perspective, and the wireless connectivity allows real-time collaboration between the onsite operator and the remote expert.

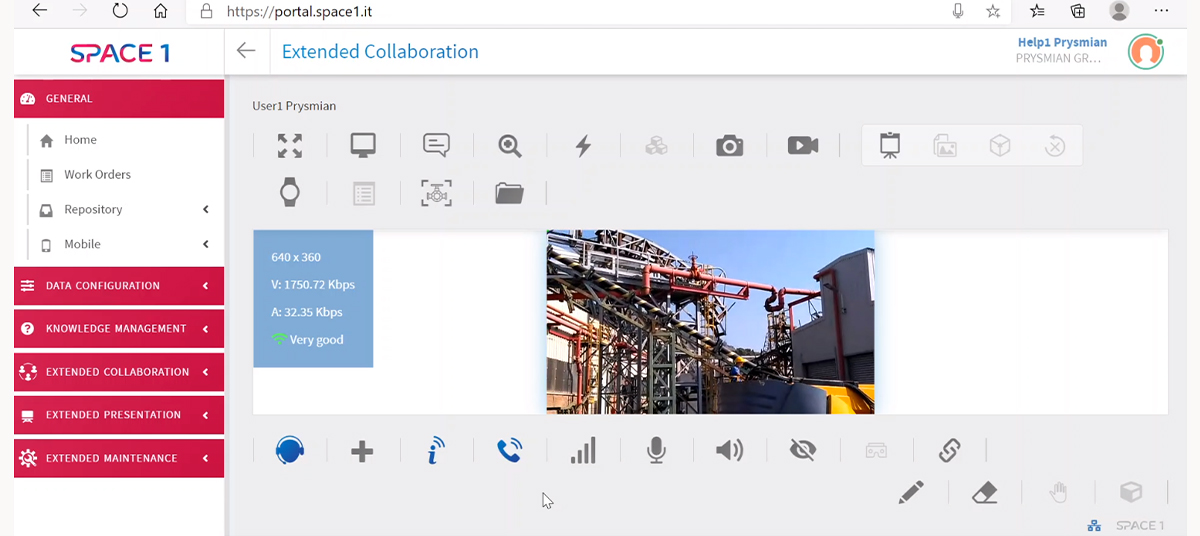

However, RealWear’s out-of-the-box integration with augmented technology platforms was the major draw. The seamless integration with OverIT’s SPACE1 solution gave field operators and their remote experts more range to collaborate and share knowledge. The remote expert is able to use SPACE1’s blend of artificial intelligence and augmented technology to better guide or mentor the field operator.

“PG Connect [with RealWear and SPACE1] completely changes the way we work,” says Carlotta Dainese, head of Prysmian Group’s Digital Innovation Lab. “It brings many benefits in terms of efficiency, as it accelerates technological transfer, and sustainability, because it reduces traveling. Lastly, it increases security, being a hands-free device that is activated by voice commands.”

“It brings many benefits in terms of efficiency, as it accelerates technological transfer, and sustainability.”

Internal Solution

Goes External

Then came the COVID-19 pandemic. Travel restrictions and social distancing guidelines prevented in-person interactions between Prysmian Group employees with its customers, which disrupted the acceptance testing process.

But what worked internally could also work for customer-facing projects.

RealWear HMT-1 running SPACE1 soon became a standard tool in system acceptance tests. While a Prysmian operator is at the site, customers and consulting systems experts connect remotely to the operator’s RealWear camera. The operator, consulting experts and customers can engage with one another in real time while maintaining social distancing guidelines.

“Our activities with customers and internal operations never stop,” says Giuseppe Pagnoni, Group Product Quality Director. “PG Connect is key for ensuring business continuity and guaranteeing real-time support to local teams provided by an internal network of subject matter experts.”

“Our activities with customers and internal operations never stop.”

PG Connect with RealWear: The Next Step to Better Service

Since deploying RealWear to various internal and external processes, Prysmian Group has seen a reduction in operation lead time and improved knowledge transfer. The time and cost savings will naturally make the company more responsive to customers’ needs.

“PG Connect is changing the way people interact and brings the company closer to its customers, while aiming at creating a new digital world that is more sustainable, reliable and efficient,” says Dainese. “PG Connect is a new digital ecosystem that enables both operators and clients to live the same experience, simultaneously, even when hundreds of miles apart.”

Solution Highlight

OverIT’s SPACE 1 augmented reality on RealWear devices connections field technicians in remote areas to more effectively collaborate with a network of engineers and technical experts

Learn more about SPACE1 integration at RealWear.com