RealWear helped Vestas’ sprawling network of field technicians and engineers access key knowledge resources, including experienced remote workers.

Vestas Wind Systems A/S manufactures, sells, installs and services wind turbines around the world. After selling its first turbine in 1979, it became the largest wind turbine company in the world in 2013 and remains as an industry leader.

The Challenge

Vestas Wind Systems faced a double challenge of a retiring workforce and transforming paper-based processes to meet the needs and expectations of younger workers.

The Solution

RealWear helped Vestas’ sprawling network of field technicians and engineers access key knowledge resources, including experienced remote workers.

The Results

- Improved knowledge sharing and training

- Increased accessibility to information

- Accelerated onboarding

- Enabled remote mentoring

Hands-Free Use Case

- Knowledge sharing

- Information accessibility

Vestas Wind Systems was founded in 1945 and operates wind turbine manufacturing plants all over the world. While it has achieved major successes since its founding, the company now has to overcome major workforce and technological challenges if it wants to continue being an industry leader.

“In the next ten years, over 30% of our workforce will retire,” says Mark Jaxion, Vestas’ Senior Specialist of Leading IoT and Industry 4.0 Strategy. “With many years of valuable experience and knowledge in the wind power industry, we are witnessing a dramatic change in the number of skilled blue collar workers.”

This will be a monumental “shift change” for Vestas with its more than 25,000 employees worldwide.

As if that wasn’t enough of a challenge, Vestas knew it also had to update how it facilitated knowledge transfer. The pace of technological updates requires a more agile system than Vestas’ traditional binders of paper documents.

“In the next ten years, over 30% of our workforce will retire…we are witnessing a dramatic change in the number of skilled blue collar workers.”

Choosing the Right Hardware

Because of Vestas work on wind turbines that can reach heights of up to 112 meters (367 feet), Jaxion and his team needed a solution that can help turbine engineers and technicians:

- Stay safe with hands-free controls

- Access the latest technical documents and multimedia

- Connect remotely with experts

Vestas’ decision to choose RealWear HMT-1 was easy since the headsets were designed with safety in mind and can be controlled entirely with voice commands. Since it’s an Android device, it can do everything a tablet can — without requiring the use of the technician’s hands.

“In the blades area, the workers can’t use their hands for navigating through the data they need,” says Jaxion. “They work with resin and carbon-fiber. There are also use-cases on a shop floor where people are basically sitting on their back the whole time while working with torque wrenches in a yaw system.”

Vestas is also looking to empower its production team with the RealWear HMT-1. “Our production team is essentially wearing hazmat suits,” says Jaxion. “In those environments, a hands-free unit is the only solution that is viable.”

With an out-of-the-box integration with Librestream, wind turbine technicians can easily connect with Vestas’ remote experts. The headset’s camera can show call participants exactly what the technician is seeing, allowing for real-time collaboration or remote mentoring. This enables a small group of experienced workers to share their knowledge at the time of need by being remotely accessible to the international network of field technicians.

“We can join a call as we’re going through the manufacturing process,” says Jaxion in a recent webinar (at the 15:24 mark). “People can watch remotely to annotate, indicate where there are problems, share PDFs or other documentation.”

“In the blades area, the workers can’t use their hands for navigating through the data they need.”

Field technicians and engineers can also access and view reference materials on the HMT-1’s high-resolution micro-display. The micro-display is compact, helping the wearer stay aware while in an elevated worksite.

Software Integrations Enhance the Solution

One of the biggest draws of the RealWear HMT-1 is its extensive technology and solution partners, including Librestream and Transition Technologies.

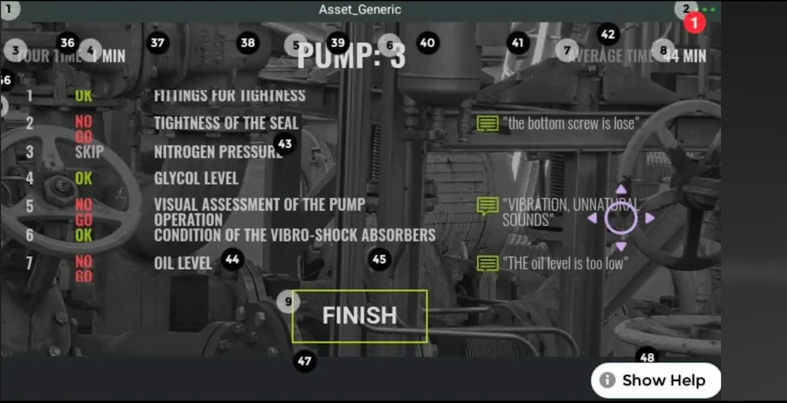

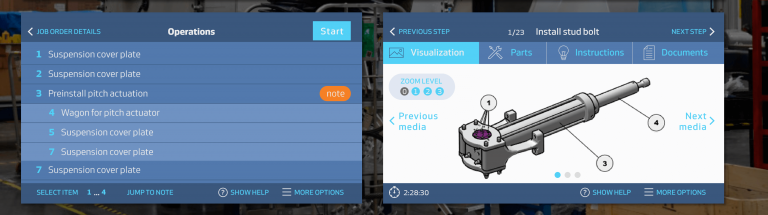

These innovative software applications allow Vestas technicians — even newly hired ones — to retrieve technical work instructions before they start an assignment. Onsite workers can interact with the data, drill down into structures and discover information that is contextualized to show visualizations of relevant parts and components.

With Transition Technologies in particular, the HMT-1 can track the wearer’s physical location to bring up locationspecific tasks. The spatial intelligence enables technicians to know where and how work needs to be completed and what actions require documentation.

“For the first time, the technology is getting out of the way,” says Jaxion. “Finally, we can allow technicians to focus 100% of their time to put value into our products. For a company like ours, a reduction in time spent on non-value-added tasks such as registration of parts or operation status is of huge importance and provides us with an extremely competitive edge.”

Solution Partners

RealWear has 77 technology partners and 14 system integrations to solve unique business challenges.

The RealWear-Transition Technologies Solution:

- Accelerated onboarding

- Improved operator training before prototype assembly

- Enabled bi-directional knowledge capture and share

- Improved information accessibility

- Enabled change request on demand

Weathering COVID-19

Since deploying RealWear’s headsets, Vestas was able to continue the ramp up of its new modular product development platform during the pandemic despite its highly skilled workers and engineers’ inability to travel.

“We have a factory in Russia where the test equipment was broken,” says Anders Thygesen, Factory Manager. “Normally, it would take three to four days for an out-ofcountry technician to be granted an

entry visa. At worst, production could stop for three to four weeks.”

However, the factory in Russia had previously received a pair of AR glasses. This meant that a Vestas technician in Denmark was able to guide a Russian colleague through repairs. The support meant that production was up and running again after four hours.

“ROI is one thing, but with COVID, this is really life support for the business,” says Jaxion.

Solution Partners

RealWear has 77 technology partners and 14 system integrations to solve unique business challenges.

The RealWear-VisualSpection Solution:

- Geotag physical assets

- Collect asset data

- Inspect components

- Complete scoping

- Remote testing